One more hindrance of vertical machining centers is that they Ordinarily have higher running expenses than horizontal machining centers. This is often to the grounds that vertical machining centers call for additional Electricity to make use of and routinely need exclusive cooling systems to forestall overheating.

Standard or Traditional machine tools make these sections with curved areas, and box/casting with closed inside cavities difficult to make with The best machining accuracy.

Any elements requiring high machining accuracy and high-quality area roughness have to be processed by machine tools, building them a crucial factor in The expansion of your manufacturing business and national economy.

This unit incorporates high-speed machining, generating the set up fast and pain-free. The Bantam Milling machine can make placing tools and element geometry almost easy employing a conductive probing system.

The table has an X-axis which incorporates the left motion and right motion, when the Y-axis includes a motion on the front and back. These axes along with the Z-axis allow you to incorporate limitless options to workpieces over the planes of motion.

It can be crucial to totally Check out the accompanying technological supplies, operation manuals, upkeep manuals, attachment Recommendations, Personal computer computer software and directions and keep them effectively, as failure to do so may well avoid the machine Software from accessing more features and make servicing hard.

You can allude to or insinuate the vertical machine centers being an industrial workhorse since it can supply parts with wonderful precision and more confined direct occasions.

In the course of the execution of the program, the operator need to be capable to immediately ascertain When the machine Device’s actions are accurate and when any preventive actions have to be taken.

Abnormal processing precision faults are widespread in CNC machine tools in manufacturing. Triggers can contain improvements in system parameters, mechanical failures, non-optimized electrical parameters, abnormal motor operation, irregular machine Device situation ring, or improper Regulate logic. To solve these types of faults, it’s vital that you establish the applicable challenges and tackle them immediately.

It’s imperative that you have a strong comprehension of the functions of each Procedure button over the machine Software:

The next are some essential issues for CNC machine choice which will fulfill your manufacturing needs;

The bottom product with the Max doesn’t supply Substantially, but There are many of selections that could be included with your obtain. A few of People increase-ons being a 4th Axis, Rigid Tapping Management, here Electronic Probe, Coolant Regulate, and A fast Resource changer option.

This is a Most important distinction between both of these machines. The orientation or composition in the spindle decides how the cutter interacts/relate Using the workpiece.

As pointed out in advance of, the milling machine excels during the flat and complex contours and lathes are most effective with the axial symmetric products. On the other hand, a CNC turning milling compound machine or turn-mill center can develop both forms of geometries by combining the potential of the lathe and mill.

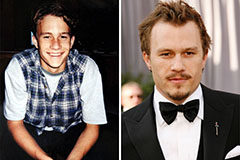

Heath Ledger Then & Now!

Heath Ledger Then & Now! Burke Ramsey Then & Now!

Burke Ramsey Then & Now! Monica Lewinsky Then & Now!

Monica Lewinsky Then & Now! Traci Lords Then & Now!

Traci Lords Then & Now! Jane Carrey Then & Now!

Jane Carrey Then & Now!